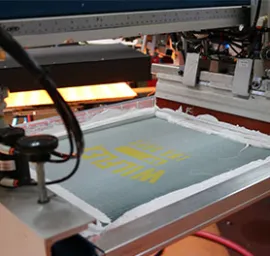

Printing Performance Wear Tips

Throughout the years, ink manufacturers have learned one unchanging truth: there is always a new fabric being developed for the market that will pose new challenges. This page reflects the challenges and approaches that lead to a solution that utilizes ink formulation, print parameters and material handling.

Ink strategy

Printing garments constructed of 100 percent polyester fibers requires ink with bleed resistance. The cure temperatures required of these inks are hotter than the cure set temperature of the dye in the polyester. The dyes start to release early in the ink cure process. Many performance fabrics also have a defined pattern on the surface, depending on the style of weave. The goal is to find an ink system and print parameter that will keep the dye migration to a minimum by utilizing low flash/cure temperatures and bleed blockers.

A low-bleed additive is also needed in this ink to battle the dye that will migrate during the cure process. In a plastisol type ink, the liquid plasticizers attract the dyes from the garment as they release from the fabric; the dyes essentially re-pigment the ink. Dyes are most actively attacking the plasticizers between 280° and 320°F. Using an under-base gray as a dye filter will also greatly enhance the bleed resistance.

Another great strategy to keep the dye migration to a minimum is to use a low-cure ink. This enables the base of the ink to cure before the all of the dye is released from the fabric (and into the ink). Since the migration starts moving once it hits 280°F, getting the ink to cure quickly greatly increases the chance to successfully stop the bleed. The under-base gray must also cure at a lower temperature or the advantage is lost.

Finally, the ink must have adequate opacity to aid in the low-cure strategy. By minimizing the amount of times that the ink is flashed, you lessen the chance for migration and over-heating the platens.

Prints that Perform

Use a soft- to medium-durometer squeegee to print at a quick speed, which keeps the ink flowing. Low-cure ink usually runs smoother when printed fast. The only limiting factor may be an under-base gray on a heavily-textured fabric.

Use only as much pressure as is needed to pass the ink through the screen; do not drive the ink into the fabric. To set the pressure on a squeegee, print the ink through the screen with multiple passes to get the ink flowing. This can be done on one scrap piece. Then, dial the pressure back and print a piece of new fabric. Keep dialing back until ink doesn’t print, then add pressure back slightly.

Flash settings

The ink’s surface temperature should reach 180°F to 200°F for 2.5 to 3.5 seconds. Use a ray-tech gun to record the platen temperature to help keep the correct settings on the flash units. The platen temperature should stay around 140°F to 160°F.

If the ink reaches 220°F or higher on the surface during the flash, the results could show blistering, bubbling or immediate bleed. This also contributes to the platens overheating, thus gelling the ink in the screen. A tip—if the flash units don’t have temperature, time or power controls, use other tricks like distance between the flash and the substrate, index time on the machine or multiple cool stations.

Cure

A low cure ink will fuse at 190°F to 300°F. It is not necessary for the ink to reach any higher of a temperature; if it does, it may lead to discoloration of the ink from dye migration. Some performance garments, such as replica jerseys, may require multiple print locations, meaning they will see two or three passes through the oven. If this is the case, over-curing will cause one side to look slightly tinted over the side that has passed through the oven just once.

The best practice in regard to time is to run the oven belt just fast enough to keep up with the machine—you do not want to hinder the production speed of an automatic. Once the belt speed is established, the oven should be set to reach the 290°F in the ink film while it is in the can. This is best measured with a thermo-probe.

Place the cross-hairs donut from the thermo-probe directly into freshly printed wet ink. Run the garment through and watch the temperature read-out. If the ink does not reach temperature, repeat the procedure with higher temperature settings. If the ink still does reach temperature, but goes higher than 5 degrees above the target, lower the temperature setting and repeat the procedure. The goal is to reach the desired temperature in the ink film for 5 to 8 seconds without going 5 degrees over.

Warning! – Combining ink systems may cause more problems than solutions. Over-cure or over-flashing of the low-cure ink may cause blistering and immediate dye migration; under-cure the general purpose ink and the result is cracking, wash failures and long term dye migration.