When you need a lightweight, strong, cost-efficient, and customizable material, composites may be the choice for you. Composites are used in many different industries, from automotive to aerospace and from infrastructure to recreation. Because composites combine resins with different types of fiber reinforcement, and can be manufactured using a variety of processes, the possibilities are nearly endless.

As such, it’s useful to explore the various types and applications of advanced composites. This comprehensive guide covers everything from the basics of composites to the properties, advantages, and common applications.

Advanced Composite Basics

What is a composite?

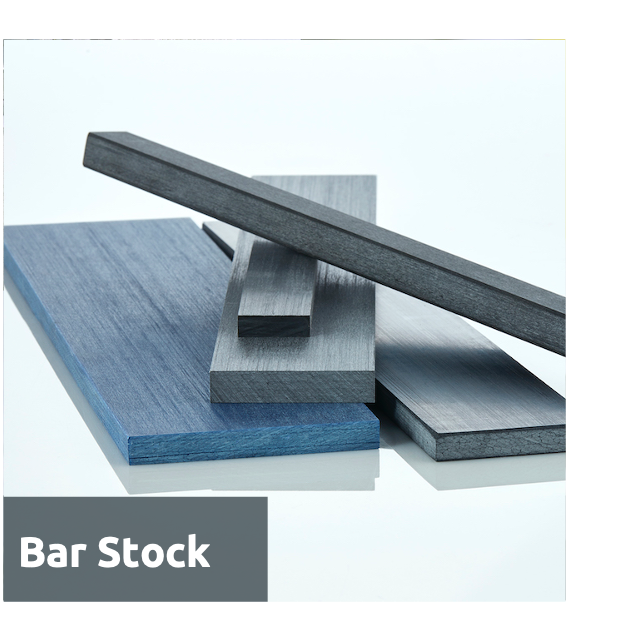

At the most basic level, a composite is a combination of two or more different materials. The resulting product generally has substantially different properties than that of the individual components. Composites can come in a variety of forms, including panels, laminates, tape or custom shapes and sizes.

How are advanced composites made?

Advanced composites, or polymer composites, are made by combining a reinforcement (such as fiberglass, carbon fiber, or aramid fiber) with a resin, which is another name for polymer. With this combination, you get the best of both worlds: strength from the fiber and the unique benefits from polymer, like fire resistance or chemical resistance. When it comes to composite manufacturing, there are hundreds of ways polymer composites can be manufactured depending on the properties, shape, and volume needed for the application. Some common manufacturing options are pultrusion, resin injection, resin transfer molding (RTM) and filament winding. Fiberglass is one of the most common polymer composite reinforcements, and carbon fiber is one of the strongest.

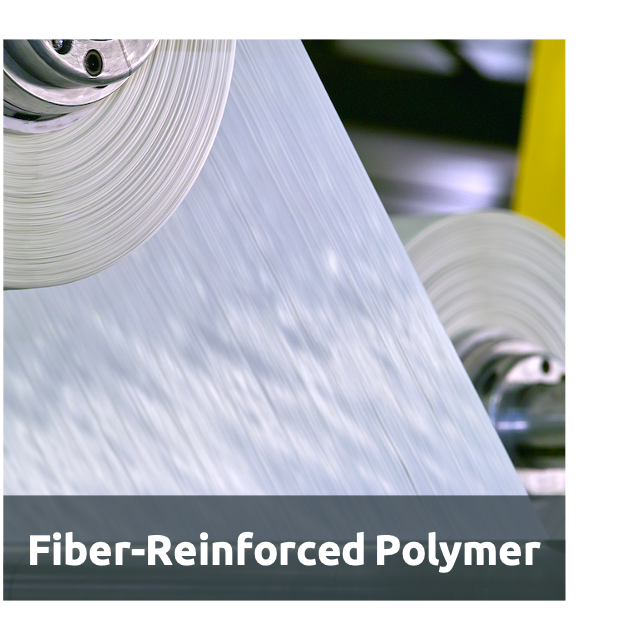

What is a "fiber composite"?

Fiber composites, more commonly known as fiber-reinforced polymer (FRP) composites, are polymer materials that have been reinforced with fiber. You may also hear these composites described as "plastic composites" or "fiber-reinforced plastic." Fiber is incorporated with polymer to add stiffness and strength to the end material.

Fiber composites, more commonly known as fiber-reinforced polymer (FRP) composites, are polymer materials that have been reinforced with fiber. You may also hear these composites described as "plastic composites" or "fiber-reinforced plastic." Fiber is incorporated with polymer to add stiffness and strength to the end material.

In researching composites, you may see them described as continuous fiber reinforced composites. A continuous fiber reinforced composite is a type of FRP where unidirectional fibers run continuously through the end product in the same direction. This creates different properties than if the fiber was split up into smaller pieces and spread throughout the resin in different directions. Overall, fibers can be continuous, long, or short in length.

How are carbon fiber and fiberglass composites made?

Like most composite manufacturing, there are hundreds of different ways you can make carbon fiber or fiberglass composites. In the most basic sense, a fiber is combined with resin. Three common ways this can be done are 1) in a way that creates a woven structure, 2) by placing the fiber fabric into a mold that is injected with resin, or 3) by pultrusion, where the fibers are pulled through resin and then shaped and cured in a heated die. Carbon fiber is known for its strength, toughness, vibration damping, and electric conductivity, while fiberglass offers excellent mechanical and insulative properties.

Properties & Applications

What are the advantages of advanced composites?

Advanced composites, or polymer composites, are prized for their exceptional strength-to-weight ratio, high stiffness, durability, and resistance to corrosion, chemicals, and environmental exposures. They can be tailor-made to deliver strength and stiffness in specific directions or certain areas depending on the use case. Because of the nearly limitless possibilities and versatility, material engineers and designers have the freedom and creativity to create new material combinations to uniquely serve new applications.

Advanced composites, or polymer composites, are prized for their exceptional strength-to-weight ratio, high stiffness, durability, and resistance to corrosion, chemicals, and environmental exposures. They can be tailor-made to deliver strength and stiffness in specific directions or certain areas depending on the use case. Because of the nearly limitless possibilities and versatility, material engineers and designers have the freedom and creativity to create new material combinations to uniquely serve new applications.

When are advanced composites used?

Advanced composite materials are often used to replace a metal, wood, or other traditional material. A polymer composite gives the product strength and stiffness, while adding benefits, such as resistance to moisture and corrosion. Using a composite reduces the weight of the part, which improves fuel efficiency and makes the final product easier to transport, handle, and install.

More specifically, FRP composites can equal or exceed the strength of steel, aluminum, and other traditional materials. If you’re looking for any of the following properties for your application, a FRP composite is worth exploring.

- Reduced weight — Composites are up to 75% lighter than steel and up to 25% lighter than aluminum.

- Durability — Composite structures have a very long lifespan, resisting fatigue and withstanding many types of weather conditions.

- Design flexibility — Composites can be molded into complex shapes and textures at a relatively low cost.

- Less maintenance — Composites are considered low-maintenance materials because they do not rust or corrode and are resistant to high temperatures.

What are some common applications for polymer composites?

Because of their vast versatility, polymer composites are already used in a variety of different industries and applications for new industries continue to be discovered. Below is a list of common industries where composite materials are often used.

Marine — Structural hull panels, decking, stringers, sail battens, cabinetry, door panels, mast structures, and anchor pins can all be made with polymer composites. Glass fiber-reinforced polyester is the most prevalent composite used in boats and ships while aramid fiber reinforcement is used in key areas of high-performance sailboats, such as the bow and keel sections. Composites are resistant to the elements and corrosive saltwater, provide high strength and stiffness, and dampen noise and vibration for a smoother ride.

Marine — Structural hull panels, decking, stringers, sail battens, cabinetry, door panels, mast structures, and anchor pins can all be made with polymer composites. Glass fiber-reinforced polyester is the most prevalent composite used in boats and ships while aramid fiber reinforcement is used in key areas of high-performance sailboats, such as the bow and keel sections. Composites are resistant to the elements and corrosive saltwater, provide high strength and stiffness, and dampen noise and vibration for a smoother ride.

Utility — Traditional wood and metal utility poles and cross arms are increasingly being replaced by polymer composites because they are non-conductive, durable, and lighter weight than wood or steel, which makes them easier to install. Glass fiber-reinforced composites are also used in other electrical transmission and distribution applications such as insulators, arresters, and pole line hardware. In all cases, polymer composites enhance performance thanks to their resistance to corrosion, heat, weather, and flame.

Utility — Traditional wood and metal utility poles and cross arms are increasingly being replaced by polymer composites because they are non-conductive, durable, and lighter weight than wood or steel, which makes them easier to install. Glass fiber-reinforced composites are also used in other electrical transmission and distribution applications such as insulators, arresters, and pole line hardware. In all cases, polymer composites enhance performance thanks to their resistance to corrosion, heat, weather, and flame.

Automotive — Polymer composites are used in several vehicle parts, including structural components, under hood and interior components, doors, seats, enclosures, bumper reinforcement, and body panels. Using composite material in automobiles can lower tooling costs and improve design flexibility for manufacturers, while improving fuel efficiency and the overall driving experience for the consumer by reducing noise and vibration.

Automotive — Polymer composites are used in several vehicle parts, including structural components, under hood and interior components, doors, seats, enclosures, bumper reinforcement, and body panels. Using composite material in automobiles can lower tooling costs and improve design flexibility for manufacturers, while improving fuel efficiency and the overall driving experience for the consumer by reducing noise and vibration.

Aerospace — Aircraft parts such as wing spars, interiors, fuselage, and radomes can benefit from the properties of composite materials. Like automotive applications, the lighter weight of polymer composites can increase fuel efficiency, resulting in reduced fuel costs for the airlines. In aircrafts, the lighter weight of composite materials also increase speed and maneuverability. In addition to lighter weight, FRP composites enable longer lasting parts that are stronger than traditional metals, and offer fatigue and corrosion resistance.

Aerospace — Aircraft parts such as wing spars, interiors, fuselage, and radomes can benefit from the properties of composite materials. Like automotive applications, the lighter weight of polymer composites can increase fuel efficiency, resulting in reduced fuel costs for the airlines. In aircrafts, the lighter weight of composite materials also increase speed and maneuverability. In addition to lighter weight, FRP composites enable longer lasting parts that are stronger than traditional metals, and offer fatigue and corrosion resistance.

Diving Deeper into Advanced Composites

Is there a difference between polymer composites, thermoset composites, and thermoplastic composites?

Polymer composites can be thermoset or thermoplastic, so thermoset composites and thermoplastic composites are both types of polymer composites. While you may also hear these composites described as “plastic composites” or “reinforced plastic,” historically composite materials are most commonly thermoset. However, thermoplastic composites are gaining traction because of their recyclability, ease of manufacturing and design flexibility. The main difference between a thermoset and thermoplastic is a thermoset cannot be reshaped after it’s formed, cured, and cooled while thermoplastics can be reheated and re-formed.

Thermoset and thermoplastic materials have different advantages and are selected based on the type of properties needed for the application. For example, thermoset composites have high temperature resistance and excellent fatigue resistance. On the other hand, thermoplastic composites have enhanced toughness, and the potential for recyclability.

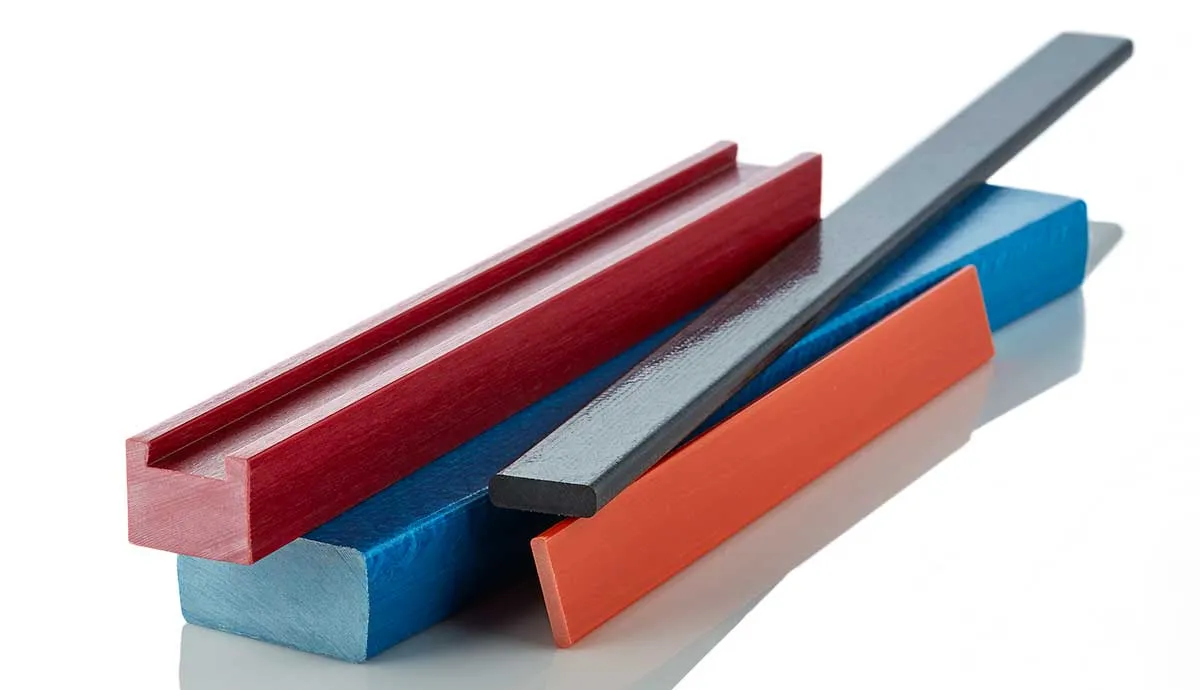

What role does pultrusion play in making advanced composites?

Pultrusion is one way that advanced composite materials can be manufactured. It is a continuous molding process where fibers are saturated with a liquid polymer, then carefully pulled through a heated die to form the parts. Pultrusion can be used to make products of virtually any length, such as beams, channels, pipes, tubing, fishing rods, and golf club shafts. If you’ve heard terms like “pultruded carbon fiber,” this simply means that a carbon fiber composite has been made through the process of pultrusion.

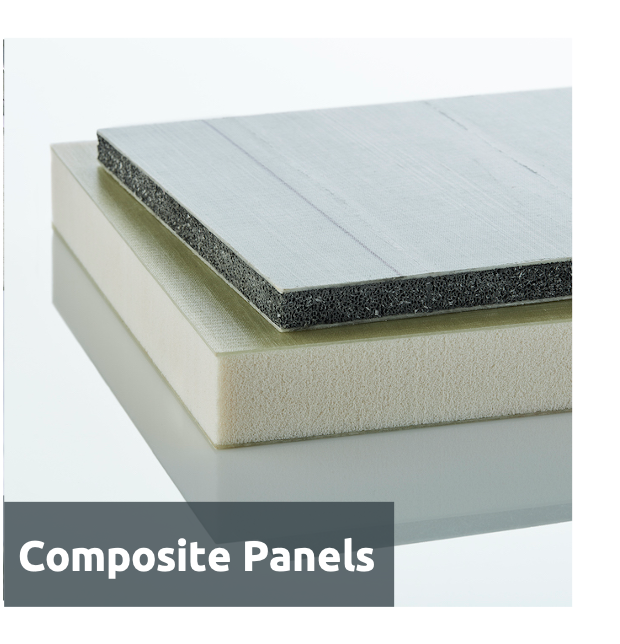

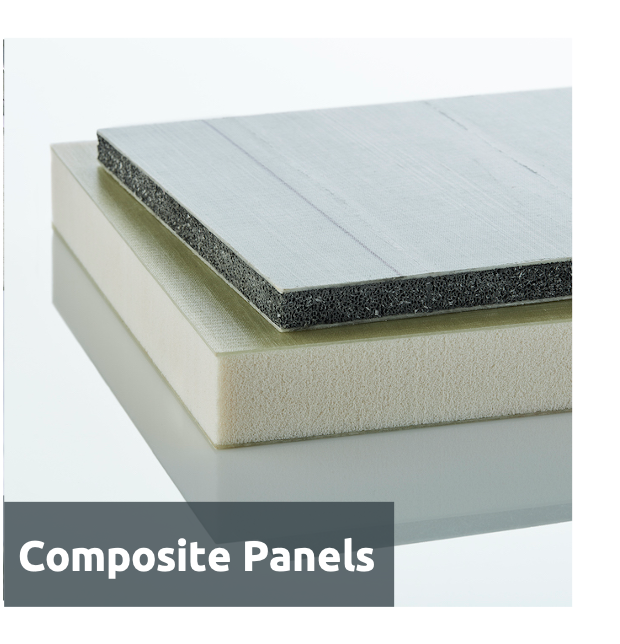

What are composite panels?

Composite panels, also called sandwich panels, are multiple layers of FRP composites layered with a core material to form a sandwich structure. The facesheets, or outside layers of a composite sandwich panel are made with composite laminates, which are layers of composite material. Depending on the application, other materials such as foam are sandwiched between the polymer laminates to create certain properties. A common thermoplastic laminate is unidirectional tape, a very thin material in which all the fibers go in the same direction as the resin. Unidirectional tape is generally manufactured in rolls, allowing long, continuously manufactured lengths of material. Organo sheets are another kind of laminate and can be made from carbon, glass, or aramid fiber fabrics.

Composite panels, also called sandwich panels, are multiple layers of FRP composites layered with a core material to form a sandwich structure. The facesheets, or outside layers of a composite sandwich panel are made with composite laminates, which are layers of composite material. Depending on the application, other materials such as foam are sandwiched between the polymer laminates to create certain properties. A common thermoplastic laminate is unidirectional tape, a very thin material in which all the fibers go in the same direction as the resin. Unidirectional tape is generally manufactured in rolls, allowing long, continuously manufactured lengths of material. Organo sheets are another kind of laminate and can be made from carbon, glass, or aramid fiber fabrics.

Ballistic panels are another type of composite panel. These panels are designed to offer protection from bullets and other projectiles and can be constructed to provide military grade protection. Ballistic panels are made from multiple layers of woven fiberglass, then encapsulated with a resin system. Common uses for ballistic panels include walls, barriers, and protective clothing.

Are advanced composites right for your product?

The best way to determine if an advanced composite is right for your use case is to discuss your needs with a composite expert. At Avient we have experts in a wide spectrum of materials to point you in the right direction.

To start, it’s best to know the kind of environment in which your product will be and what kind of properties you need (e.g., heat or water resistant, hard or soft, color). Our mission at Avient is to solve the world’s most complex material science problems, and that means supporting you from research and development through to production. Contact us today to get started.

Fiber composites, more commonly known as fiber-reinforced polymer (FRP) composites, are polymer materials that have been reinforced with fiber. You may also hear these composites described as "plastic composites" or "fiber-reinforced plastic." Fiber is incorporated with polymer to add stiffness and strength to the end material.

Fiber composites, more commonly known as fiber-reinforced polymer (FRP) composites, are polymer materials that have been reinforced with fiber. You may also hear these composites described as "plastic composites" or "fiber-reinforced plastic." Fiber is incorporated with polymer to add stiffness and strength to the end material. Advanced composites, or polymer composites, are prized for their exceptional strength-to-weight ratio, high stiffness, durability, and resistance to corrosion, chemicals, and environmental exposures. They can be tailor-made to deliver strength and stiffness in specific directions or certain areas depending on the use case. Because of the nearly limitless possibilities and versatility, material engineers and designers have the freedom and creativity to create new material combinations to uniquely serve new applications.

Advanced composites, or polymer composites, are prized for their exceptional strength-to-weight ratio, high stiffness, durability, and resistance to corrosion, chemicals, and environmental exposures. They can be tailor-made to deliver strength and stiffness in specific directions or certain areas depending on the use case. Because of the nearly limitless possibilities and versatility, material engineers and designers have the freedom and creativity to create new material combinations to uniquely serve new applications. Marine — Structural hull panels, decking, stringers, sail battens, cabinetry, door panels, mast structures, and anchor pins can all be made with polymer composites. Glass fiber-reinforced polyester is the most prevalent composite used in

Marine — Structural hull panels, decking, stringers, sail battens, cabinetry, door panels, mast structures, and anchor pins can all be made with polymer composites. Glass fiber-reinforced polyester is the most prevalent composite used in  Utility — Traditional wood and metal

Utility — Traditional wood and metal  Automotive — Polymer composites are used in several vehicle parts, including structural components, under hood and interior components, doors, seats, enclosures, bumper reinforcement, and body panels. Using composite material in

Automotive — Polymer composites are used in several vehicle parts, including structural components, under hood and interior components, doors, seats, enclosures, bumper reinforcement, and body panels. Using composite material in  Aerospace —

Aerospace —  Composite panels, also called

Composite panels, also called