Find the Best Long Fiber Solution

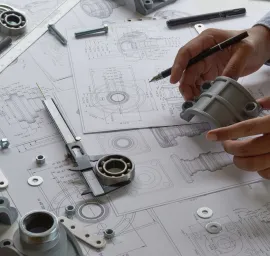

Long carbon and glass fiber reinforced thermoplastics are structural injection molding composites with metal replacement performance. Leverage their tougher, stronger, and lighter capabilities today.

We manufacture specialty long fiber composite pellets using a proprietary pultrusion process that melt impregnates continuous carbon, glass or other specialty fibers with thermoplastic polymer matrices ranging from polypropylene (PP) to PEEK to achieve high performance. Our composite pellet products are formed into finished articles by processors using injection molding and are sold globally under the tradenames of Complet and OnForce.

Long fiber thermoplastics (LFTs) are fiber-reinforced composites used to replace metals or other under-performing thermoplastic solutions that don't stand up to the needs of demanding structural applications. Avient has capabilities to assist you throughout an entire product launch - through product design, performance analysis, composite selection, composite pellet production, first article runs at our facility, and, finally, collaborating with your selected injection molder to ensure success. Agility is one of our defining cultural characteristics; our team is used to working on fast-paced timelines while always remaining committed to obtaining our success by ensuring our partners succeed.

Our manufacturing and application development center is located in Winona, Minnesota. We have composite pellet manufacturing in North America and Europe guided by the ISO 9001:2015 certified quality system.

In 2018 PlastiComp became a part of Avient Corporation to expand the reach for our unique materials and business methodology.

Solutions and Technologies

- Long Fiber Solutions

- Long Carbon Fiber Reinforcement

- Long Glass Fiber Reinforcement

- Long Hybrid Reinforcement

- Performance Additives

- Long Fiber Technologies

- Complēt™ Long Fiber Reinforced Structural Thermoplastics

- Complēt™ MT Long Fiber Composites

- Complēt™ Moisture Resistant Nylons

- Complēt™ PKE Formulations

- Complēt™ REC Formulations

- OnForce™ Long Glass Fiber Reinforced Polypropylene Composites

- Surround™ EMI/RFI Shielding Formulations